IMPREGNATION SERVICES LTD

Porosity Sealing

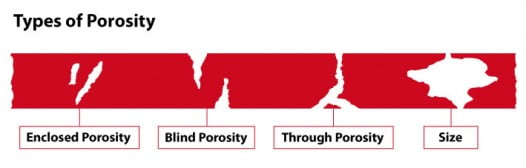

The impregnation process to seal porous castings and other materials can be carried out using several methods, a few of which are listed below.

Porosity sealing is critical when it comes to the use of castings, specifically in industries where structural integrity and performance are paramount. ISL boasts state of the art in-house twin impregnation process lines, which allows us to offer a porosity sealing uptime of 100%.

For over 60 years, we have been offering expert casting impregnation services specialising in vacuum impregnation.

Through our porosity sealing services, ISL can help you become more environmentally friendly, preventing you from needing to waste porous or leaking castings.

Vacuum and Vacuum Pressure Impregnation Process

We provide Vacuum and Vacuum Pressure Impregnation using industry leading thermo curing polyfunctional methacrylate resins.

Internal Pressure Impregnation Process

Large castings occasionally outsize our conventional vacuum process lines. In these cases, we are usually able to fill the casting with suitable resin and apply air hydraulic pressure to force the resin into the porosity.

Graphite Impregnation Specialists

Impregnation Services retain specialist knowledge in impregnation of Graphite Electrodes and specialist parts. We offer both linseed oil impregnation and methacrylate resin impregnation to an established international customer base.